YETI Coolers – 2024

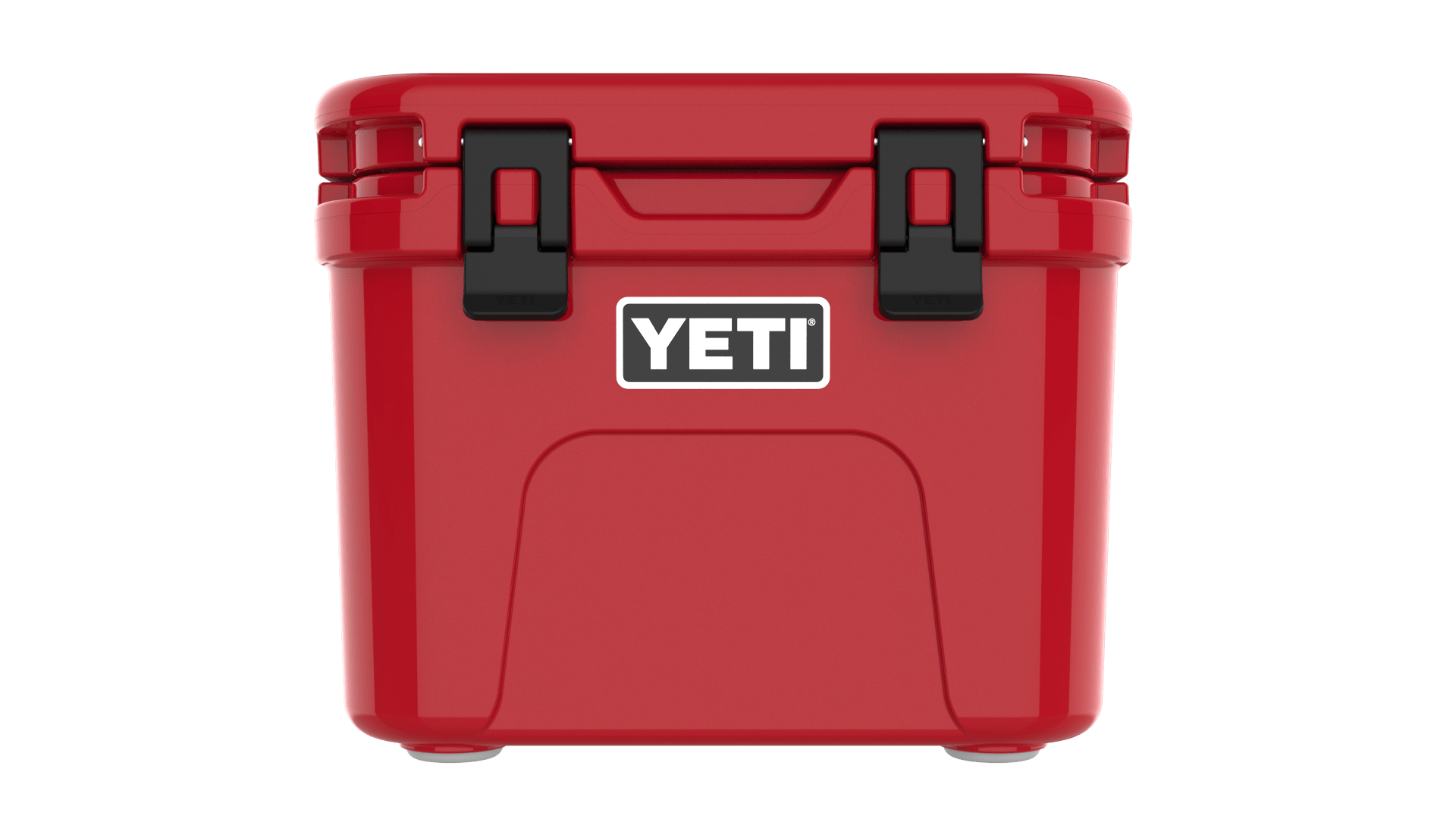

Launched in Q3 2024, the Roadie® 15 is a compact cooler built for everyday adventures. It delivers YETI’s legendary durability and ice retention, now in a more portable size. The Roadie® 15 features an innovative strap for comfortable carrying by hand or on the shoulder, a drain plug for quick-draining convenience, and versatile mounting options for securing it almost any vehicle you can imagine. Thoughtfully designed with features like wine bottle compatibility and a dry goods tray, the Roadie® 15 elevates the on-the-go experience, keeping contents cold, organized, and accessible.

Role:

As the sole mechanical engineer on the project, I was heavily involved from concept to production. I collaborated with our Industrial Design and Product teams to generate design concepts, develop prototypes, and finalize the design specifications.

From there, I partnered with suppliers in both Thailand and Mexico to finalize the design with tooling considerations. The process culminated in a visit to the supplier in Thailand to oversee the initial engineering build and troubleshoot various manufacturing issues.

My role also included comprehensive product testing, both in-house and at the supplier’s facilities, to ensure the highest quality and performance.

This project, of which I am most proud, exemplifies my comprehensive approach to product development.

Design Considerations:

- Optimize dimensions for capacity, thermal performance, and carrying comfort

- Engineer a robust latch with a secure, splash-resistant seal that minimizes pressure differentials

- Ensure effortless draining with a newly designed, leak-proof drain plug

- Design a comfortable and versatile strap that can be configured for hand or shoulder carry modes

- Design versatile mounting points for stable attachment to various surfaces and vehicles

- Develop an innovative, patent-pending strap attachment method that allows for easy removal

- Collaborate closely with global suppliers to optimize tool design for consistent quality across manufacturing locations

- Conduct rigorous testing to ensure durability and performance under extreme conditions

Manufacturing Processes:

- Injection Molding

- Compression Molding

- Insert Overmolding

- Post-Tool Machining

- Electromagnetic Welding

- Spin Welding

- PU Foam Injection

- Silicone Foam Extrusion

- Soft Goods Manufacturing

Materials:

- Polypropylene (PP)

- Glass-Filled Nylon (PA)

- Polyacetal (POM)

- Silicone Rubber

- Polyurethane Foam