LEED Fabrication – 2012 to 2017

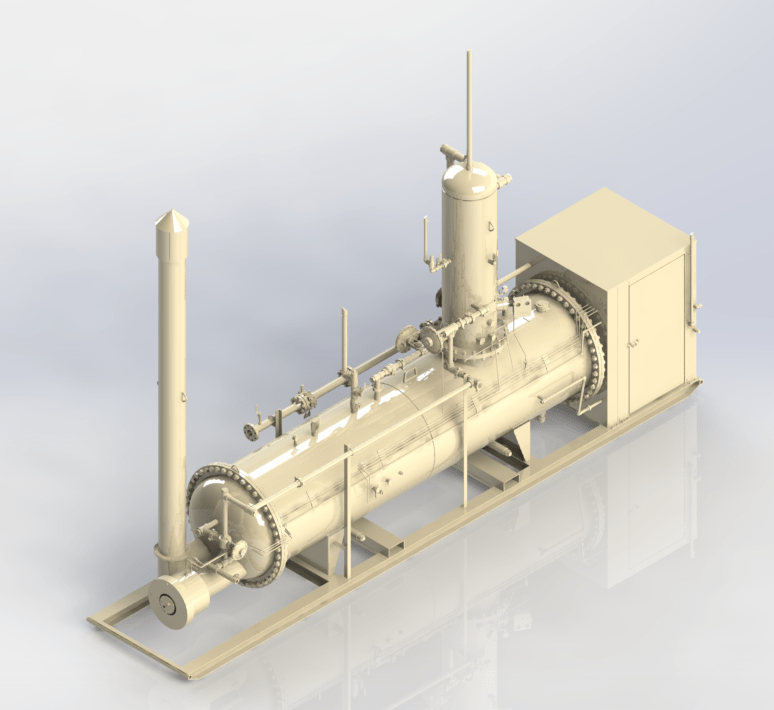

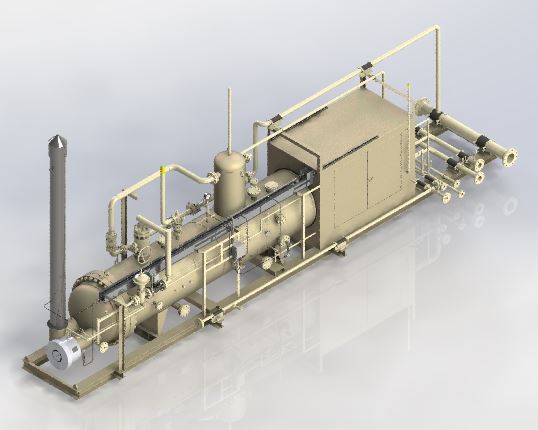

Designed for deployment in the Northern Great Plains, pressure vessels use a combination of heat, pressure, and time to separate wellhead fluids into oil, gas, and water constituents.

Role:

What started as a temporary contract to create 3D CAD models developed into 5 years of experience designing separators, heater treaters, combustors, and flares. Each vessel was custom designed and outfitted to meet customer specifications.

Certifications:

- ASME B31.3 Process Piping Design

Design Considerations:

- Develop and maintain CAD library for inventory of valves, fittings, hardware, regulators, and measurement devices

- Utilize ASME design software for vessel sizing calculations

- Ensure strict adherence to industry safety and design standards

- Design sheet metal enclosures to protect measurement equipment in harsh environments

- Support on-site manufacturing to ensure drawing specifications are met

- Manage 500+ part CAD assemblies, with complete 2D drawing packages and revision control

Manufacturing Processes:

- Arc Welding

- Plasma Cutting

- Sheet Metal Stamping and Forming

Materials:

- Carbon Steel