Fluence Bioengineering – 2018

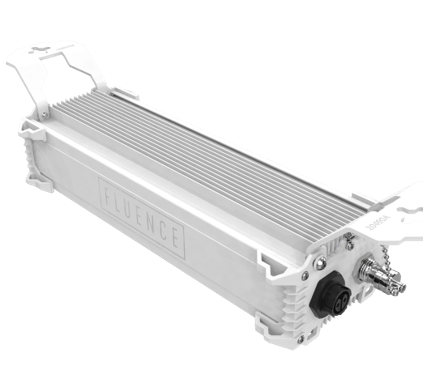

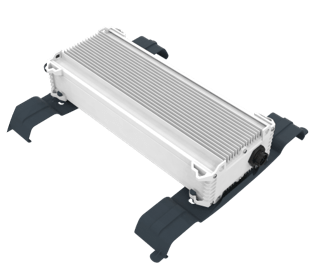

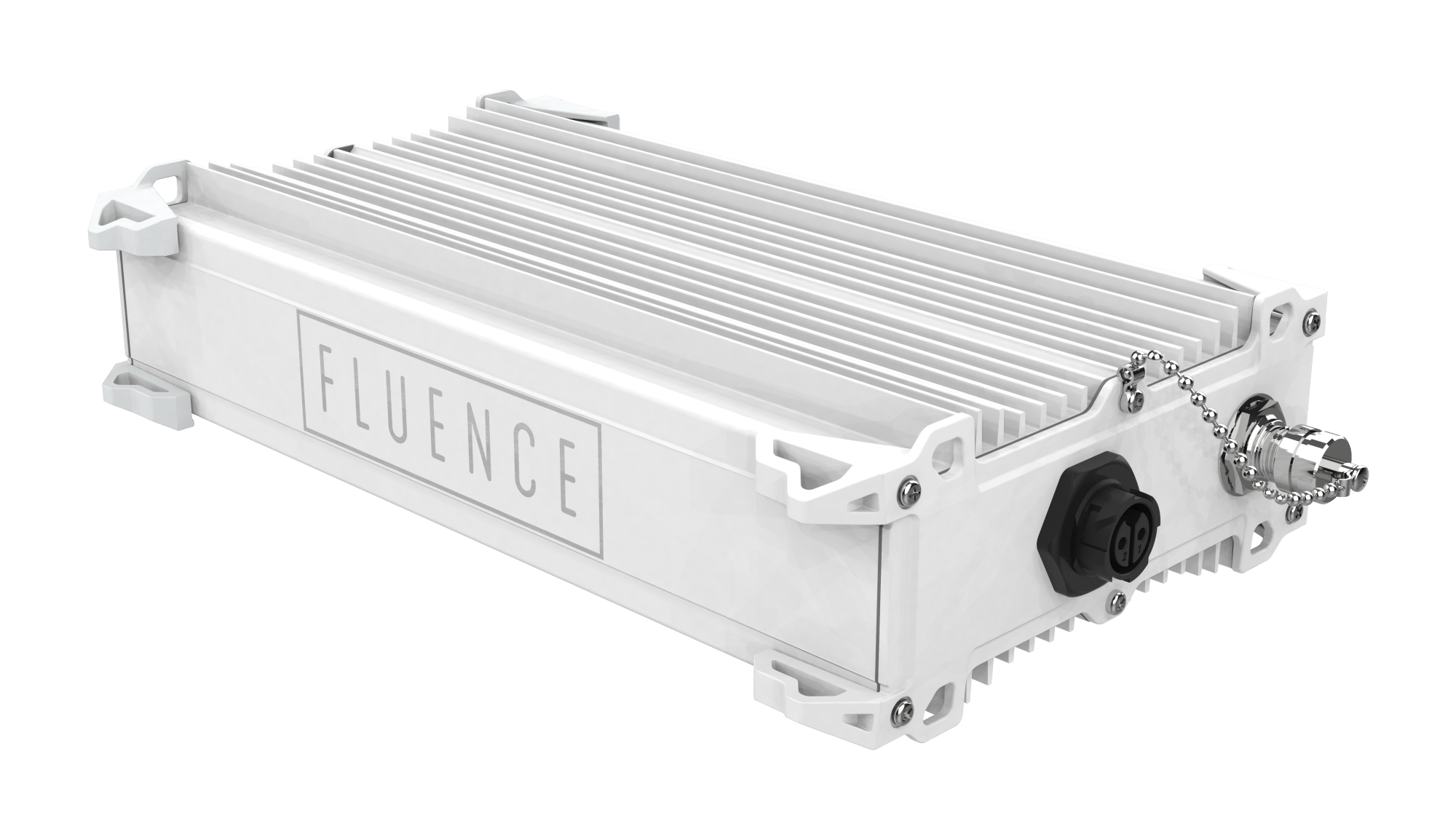

The power supply unit (PSU) leveraged relationships with external vendors to manufacture a custom case design that offers unparalleled functionality. Unlike traditional power supplies that only accommodate surface mounting, the PSU adds attachment points for wireforms and a variety of plastic and sheet metal brackets.

Furthermore, the supply firmware was updated to mirror output specifications that were previously managed with external control circuitry. Replacing a complex assembly of over 30 parts, the PSU offers expanded hanging versatility with a 35% reduction in cost.

Role:

Managing development at multiple suppliers, I created the initial design concepts and oversaw production to ensure design intent was maintained. Working alongside our Electrical Engineering team, supply outputs were meticulously tuned for optimal performance.

Design Considerations:

- Redesign of the aluminum case to enhance functionality and aesthetics

- Initialize laser etched branding and certification labels

- Develop variable case dimensions to accommodate existing control circuitry

- Maintain backwards compatibility with legacy hanging hardware

- Develop accessory brackets for surface and fixture mounting

- Manage connector upgrades for enhanced EMI performance and product certifications

Manufacturing Processes:

- Injection Molding

- Metal Extrusion

- Aluminum Die Casting

- Sheet Metal Stamping and Forming

Materials:

- Anodized Aluminum

- Polycarbonate (PC)